- kesyaipl2@gmail.com

- Rajdhani Park, Mubarkpur, Delhi, 110041, India

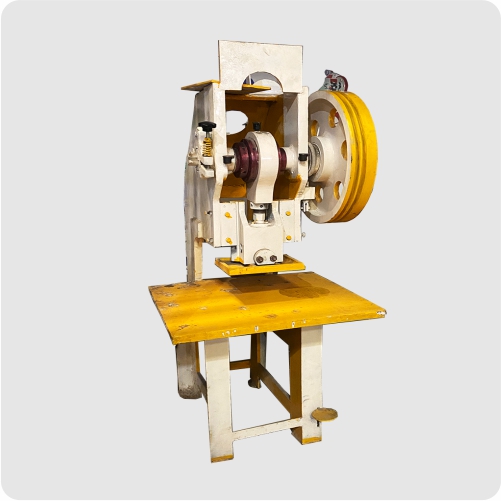

Chappal Making Machine

Manual slipper making machine with spring

Buy the best manual slipper making machine in Delhi from Kesya International Private Limited. This manual slipper-making machine is a small powerhouse that produces remarkable outcomes when used to make chappals or slippers by hand. Despite its modest size, it can make up to 250 pairs of fashionable, handcrafted-grade slippers every day, assuring consistent, high-quality production. The machine's simple yet effective design contains a die/mold, metal frame, pressing plate, and lever (with spring). The pressing plate and dies deliver accurate cuts and forms to rubber and EVA sheets, with sharp blades that can handle materials ranging from 4 mm to 18-20 mm thick. This adaptable machine is ideal for small enterprises or entrepreneurs that want to maintain high-quality standards while using little resources. Its simple operation allows workers with no technical experience to utilize it, making it a good alternative for emerging businesses.

Enquiry.jpg)

Manual slipper making machine with bearing

Buy the best manual slipper making machine in Delhi from Kesya International Private Limited. This compact, bearing slipper-making machine is designed for producing high-quality, hand-finished chappals and slippers with ease. Its sturdy metal frame, paired with a pressing plate and lever, is synchronized with a ball-bearing mechanism that streamlines the production process. Capable of crafting over 300-350 pairs of stylish chappals—potentially more depending on the operator's skill—this machine is ideal for artisans and small workshops focused on quality over quantity. The ball-bearing system minimizes friction, ensuring smoother operations, extending the machine's lifespan, and enhancing the precision of every cut. It's an excellent choice for those seeking to maintain high standards with a straightforward, reliable tool.

EnquiryBesides having high production capacity, this hydraulic slipper maker is designed in a manner that ensures durability and operation without interruption for long-term reliability even under high-volume manufacturing applications.

This hydraulic system smoothes each cut and mold with increased precision, besides reducing the total wear and tear of the machine to extend its life. That makes it a very good option for any manufacturer who intends to scale up production with minimum maintenance costs. The user-friendly interface and smooth operation mean operators can produce quality workpieces with little effort, even when technical experience is at a minimum.

Automatic slipper making machine

This automatic slipper-making machine is basically one piece of equipment incorporating the latest technology in the production of chappals for the automation of high-quality chappal output. The rate of production is quite good-from 700 to 1,800 pairs of chappals per day. The multimodal machine integrates material loading, material heating, molding, cutting, assembling, and finishing to ensure smooth and uniform production over long, uninterrupted hours. We do have variants of the machines depending on what pressure they are going to apply, like 5 tons, 10 tons, 15 tons, and 20 tons. Its weight is from 300 kg to 700 kg, depending on its work efficiency. Due to the capability it has for combining quality and quantity of production, the machine is very effective for large-scale production. It has a solid structure, advanced features, very stable performance, and a long service life.

Enquiry